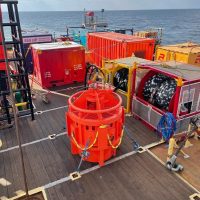

JBS Fabrication Ltd subsea excavation services provide mass/controlled flow excavation (MFE/CFE) subsea excavators and auxiliary equipment using our patented Sea Axe. The equipment is available for lease and sale complete with a full complement of experienced operational personnel available 24 / 7 to support Sea Axe operations globally. Sea Axe is manufactured by JBS in the UK.

Sea Axe CFE equipment is the best available technology for subsea and pipeline excavation in the oil & gas, renewable energy and decommissioning sectors.

Sea Axe subsea trenching capabilities have evolved from the traditional mass flow excavation subsea technology. Sea Axe is set to lead the market in subsea controlled flow excavation. Sea Axe works through natural erosion of the seabed hence it is the most environmentally acceptable method available for subsea excavation. Natural erosion significantly reduces the impact on the ecological environment.

The Sea Axe excavator is easily adaptable and can excavate a wide range of seabed materials up to 200kPa shear strength using the in-built auxiliary jets.

Sea Axe will meet specific project requirements such as rock, sedimentary displacement or seabed preparation.

Sea Axe can remain in the water for up to 72 hours and requires minimal maintenance.

Sea Axe is a non-contact and non-intrusive mass flow excavator, making it ideal for offshore windfarm subsea cable work or reducing stress on live cables via high-spot subsea excavation.

Our Subsea excavation services include:

- Subsea trenching

- Pipeline excavation and deburial

- Subsea engineering

- Mass flow excavation

- Subsea Dredging

- Freespan Correction and Seabed Rectification

- Access to subsea structures

- Windfarm Cable Array and Export Trenching / De-burial

- Cable Joint Burial / IRM

- Jack-up Leg / Spud Can Clearance

- Harbour / Pontoon Seabed Clearance

- UXO De-burial / Access

- Cable and Pipeline Route Clearance

- Umbilical & Flowline Trenching and De-burial

- Salvage De-burial / Access

- Access to Subsea Structures / IRM / Decommissioning

- Subsea Cable Location and Recovery

- Umbilical / Pipeline Recovery

- Rock Dump Dispersal

- Subsea Pipeline and Cable Installation

- Small deck space – only 8m x 10m required on vessel

Sectors

- Oil & Gas

- Marine

- Defence

- Renewable Energy

- Ports and Terminals